201641038846: ELECTRICAL MACHINE FOR A VEHICLE

Pending

This patent is filed in multiple countries through PCT route, and examination is in progress.An objection was raised by Chinese patent office and the following was provided to the patent agent.

Supporting documentation

In the application 201641038846, the IC engine starting application is only a preferred embodiment, and not a limiting application.

201641038846 mentioned the following:

"wire which was pressed against the sharp edge of the tooth will have the enamel coating damaged, and can cause body short with the phase connection"

This says that 201641038846 is looking into this configuration to avoid damages to the wire enamel coating and hence avoid body-short with phase wires. Hence the application is not just increasing the copper thickness to increase current through the wires, by primarily focused on avoiding the damage to the wires.

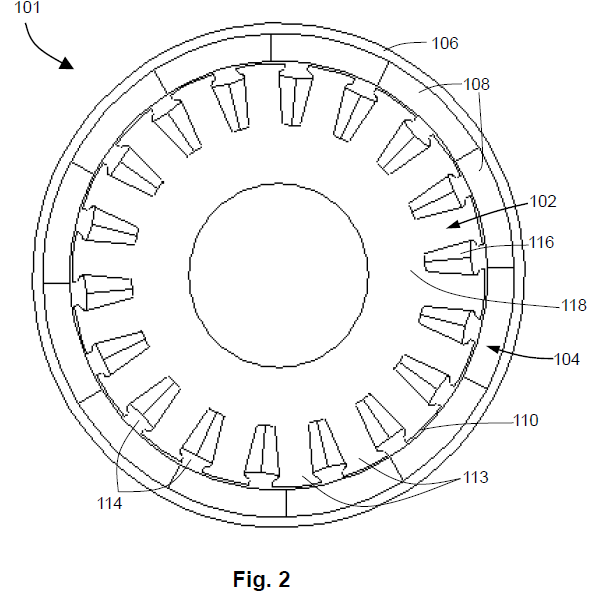

201641038846 is focusing on the tooth edges, to be smoothened or chamfered, not focusing on a full curve as mentioned in CN107026519A. CN107026519A talks about two curved surfaces, and two flat surfaces.

The premise, intent and the result of operation is completely different:

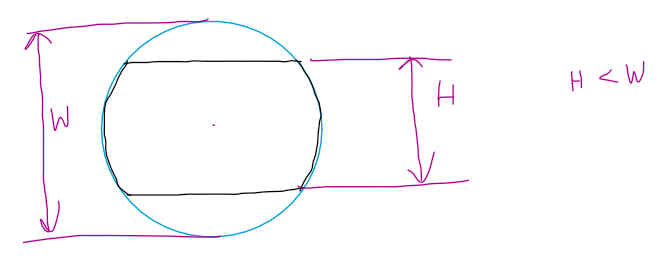

CN107026519A specifically says that W is distance between curved surfaces, and H is the distance between flat surfaces. The definition of these surfaces is so strong that the following relation is also proposed in the claim. 1> H/W > ½.

This means that for the winding stem, the height has to be less than width, and height has to be more than half the width.

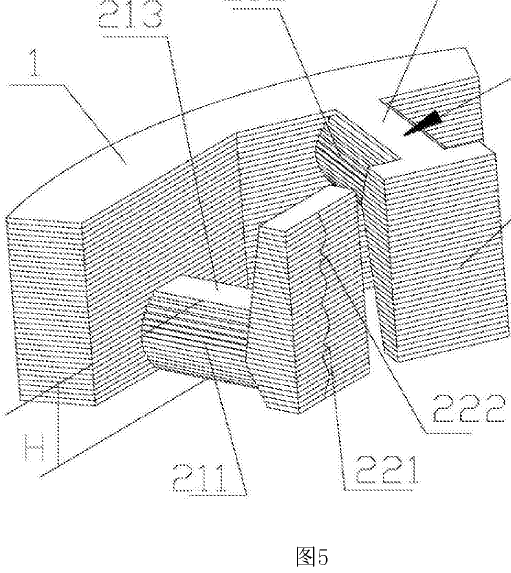

CN107026519A also states that the neck part of the iron core is approximately circular. The following image gives a better representation of how the stator winding stem is constructed (black).

Please also refer to https://patents.google.com/patent/CN107026519B/en for better translation.

Figures 3,4,5,6,7 and 8 (more specifically figure 5) of CN107026519A refers to a more detailed construction of the stator winding stems such that the adjacent stems are not planer. This kind of construction is focused on achieving the circular side profile of the stem so that more copper can be filled in.

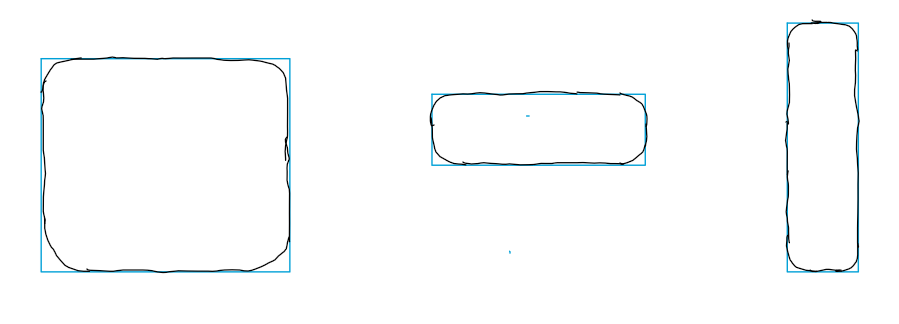

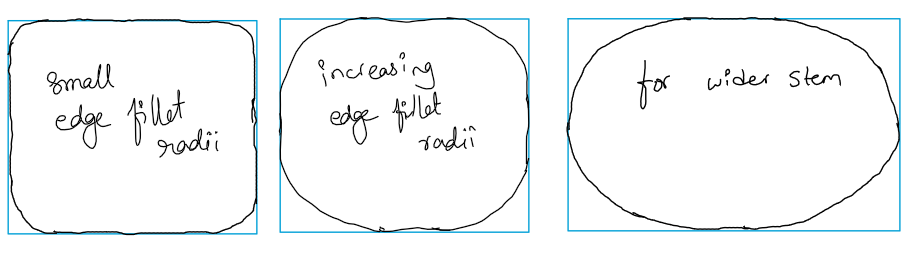

201641038846 specifically has stated that it is only focusing on all the edges to introduce a curvature or chamfer or smoothening. The following figure demonstrates this.

An extreme case of 201641038846 points to a small part of CN107026519A.

When the fillet radius is increased beyond a threshold so as to reach half the thickness (effectively forming a semi-circle at each side), and when the stem width is more than the height, 201641038846 comes close to CN107026519A, but not same. CN107026519A defines half the stems in one plane, other half in another plane.

201641038846 defines all the stems to be planar.

CN107026519A defines all side surfaces of stems to be circular, 201641038846 has flat region, and the chamfer/fillet radius regions. They are very different in construction, and have different inspirations.

Clearly, application 201641038846 is not derived from CN107026519A. The date of publication of CN107026519A (2017 August) is later than the priority date of 201641038846The solution is inspired from a very different domain, and originated from a very different source of problem, and CN107026519A would not have inspired the inventors to make changes to the invention so as to result in the present patent application.

The automotive engine starting application is very relevant in this case. The starter motor is mounted on the engine case, whose temperatures go much higher than 150 degC. It is common knowledge (imperative) that the motor mounted on the vehicle gets exposed to very high temperatures and gets heated. The conductive heating of the stator coil results in expansion of the winding copper, which may increase in the tension in the wire resulting in the wire-coil to be more tightly hugging the winding stem. Without the proposed inventive step of introducing the smoothed edges, the wires tend to get damaged enamel, resulting in shorted phase wires, and eventually drained battery (power source on the vehicle) and loss of performance of the motor.

Hence, the application 201641038846 is very specific to deriving the solution to the problem that occurs in automotive domain. The possibility of more space that allows us more copper is only a derivative benefit of the actual solution.

• 201641038846 may propose a narrowing claim that the fillet radius is limited to maximum 75% of the winding stem width so that near-zero width laminations need not be prepared.

• 201641038846 may also propose a narrowing claim that the fillet radius is limited to a max of 75% of the winding stem height so that the circular arc shape on the edges can be avoided in the scope.