2758/CHE/2008: A DEVICE FOR INDICATING THE STATE OF ACTIVITY OF PRE-SELECTED EQUIPMENT INSTALLED IN A MOTOR VEHICLE

Status

An objection was raised by Indian patent office and the following was provided to the patent agent. However, this patent was not granted on the grounds that the cited documents disclose the invention. A prior-art search at the time of drafting and claim scope analysis would have saved this patent.

Supporting documentation

2758/CHE/2008's novelty and inventive step are the three items mentioned in the differences below. In light of the suggested prior art, 2758/CHE/2008 may not claim the placement of the vibration generator in the handle bar, but 2758/CHE/2008 can claim the construction and implementation of vibration generator. 2758/CHE/2008 might have to merge claim 1 with few sub-claims.

Similarity with suggested prior art : Has the vibration generator mounted in the vehicle (handlebar)

Differences from prior art:

1. construction and implementation of the vibration

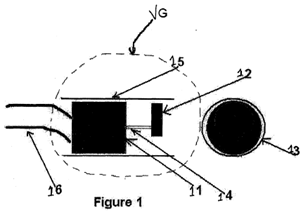

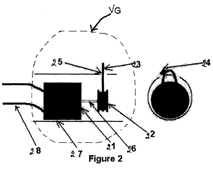

a. 2758/CHE/2008 talks about the motor with an eccentric load mounted on the shaft.

b. 2758/CHE/2008 talks about the motor with a shaft connected to the pulley, the pulley’s outer surface has a projection that taps users’ palm when the motor rotates

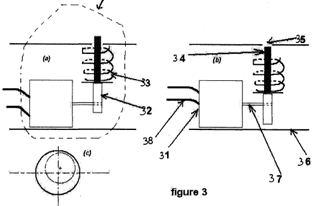

c. 2758/CHE/2008 talks about the motor which has eccentric shape at the shaft end, that drives the plunger back and forth, with the help of a spring element. This is different from the solenoid-plunger that moves because of the electromagnetic effects.

2. frequency of vibration to avoid fatigue of parts

a. The third embodiment talks about the motor’s rotational speed limit to avoid fatig

ue failure of the spring.

3. Frequency of vibration and placement of vibration generator to avoid resonance

a. It was mentioned in the description that the frequency of vibration was such that the it is not a multiple of natural frequency of the structure of handlebar.

b. It was also mentioned in the description that the location of vibration generator should be such that the it does not resonate with the handlebar during vibration.

The suggested prior art

D1:

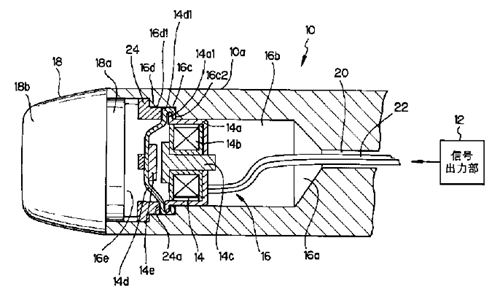

Similarities: motorcycle, handlebar, grip part, signal output part

Differences: oscillation generating part construction – ring shape coil ,fixed iron core and movable iron core . This is a standard solenoid implementation.

D2:

Similarities: vibration generator mounted in the vehicle

Differences:

1. the vibration generator is mounted in the seat/backrest/tank sidewall. This patent did not mention the handle bar.

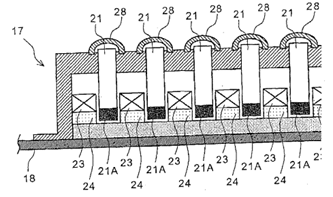

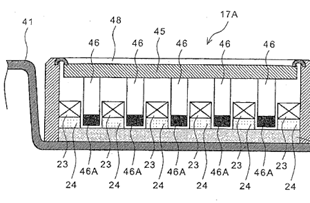

2. The vibration generator is solenoid based. It has multiple solenoids with multiple plungers ( addressed as pillar-shaped movable members)

D3:

Similarities: vibration generator is installed in the handle portion

Differences:

1. To indicate when the vehicle is moving backwards

2. This describes the DC motor with magnets and brush setup; the motor is molded in synthetic resin, but the vibration source is not identified. No eccentric, etc

a. The controller changes the applied voltage for changing the vivration level.

b. This document assumes that the vibrations are produced from the normal motor run only, without any constructional changes in the motor or at the shaft.

3. The vibration is divided in to multiple phases and correspondingly the motor is run.